Destination

Belt conveyors type – PTP are intended for technological transport of bulk materials of all kinds of granulation 1-100 mm, a humid that do not cause permanent adhesion to the belt and conveyor construction elements. These conveyors are used everywhere where it is necessary to quickly and accurately transport the material to distance specified by the range of one or more coupled conveyors.

The construction

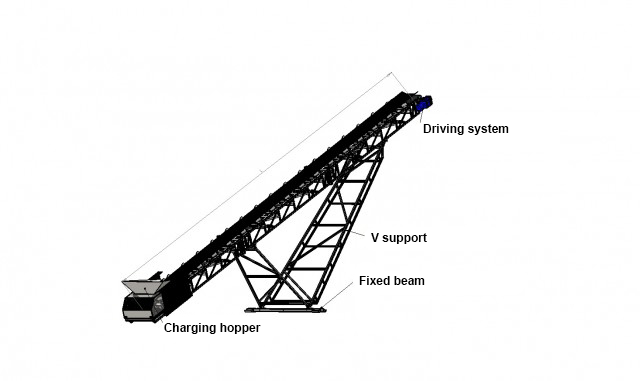

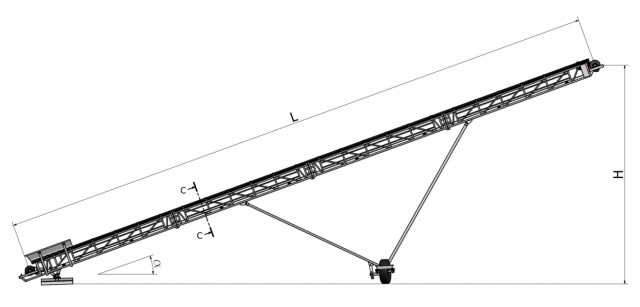

The construction of the conveyor – welded, made of pipes and steel shapes, protected by anti-corrosion coating. The conveyor can be equipped with a charging hopper, its size and location depends on the purpose and conditions for cooperation with other technological devices. The support method- fixed or adjustable. The drive – electric via the reduction gear and the reduction gear. Conveyors can also be equipped with climatic shield and (or) one or two-sided platform.

Work

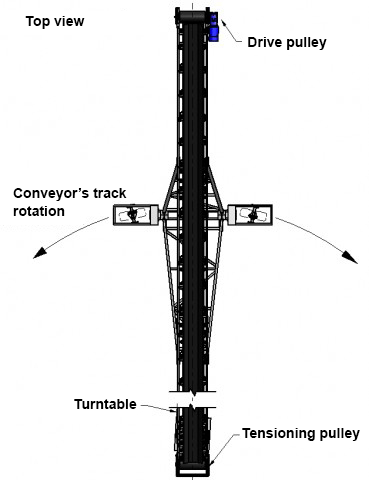

Basic working position – diagonal. Start-up after turning on the power supply – manually or automatically. Turning the power starts the drive pulley and the movement of the belt conveyor. Adjusting screws are used to regulate the working belt tension by changing the spacing of the pulley.

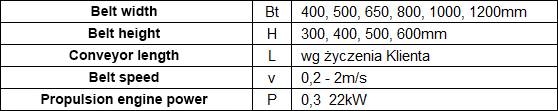

Technical specifications

5. Types of the belt conveyors

Belt conveyor on V-shaped support and a fixed beam

Systems used in belt conveyors

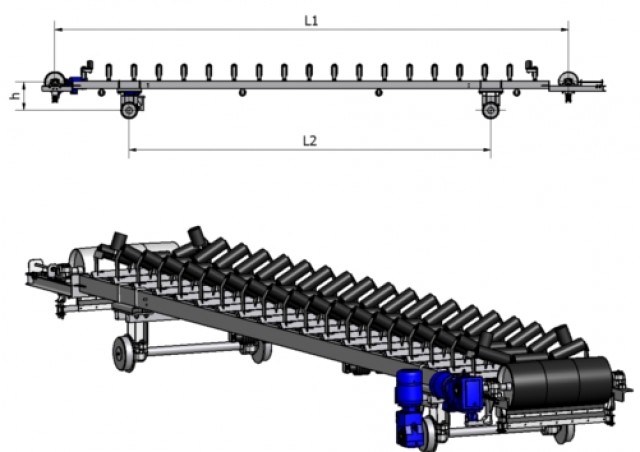

C- profile

• Flat system